The Welding Research Council or WRC 107/297 and 537 bulletins help engineers and designers to better determine allowable nozzle loadings and stress analyses for piping systems, pressure vessels and heat exchangers.

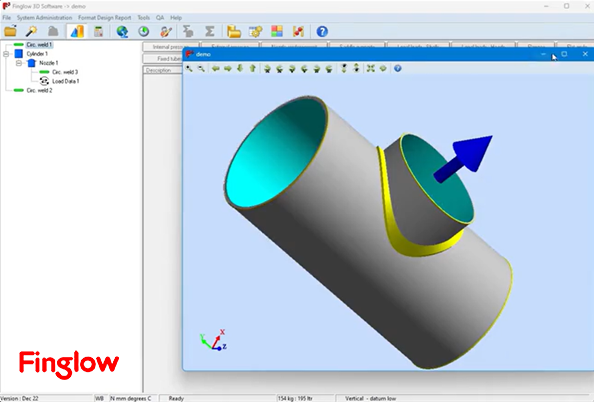

With Finglow, CEI's engineering solution for designing pressure equipment, users can validate their designs against global codes like PD5500, EN13445 and ASME Section VIII Div 1 and 2 to ensure their designs are cost-effective and compliant.

Recently, Finglow announced a new integration with Paulin Research Group, a by-product of CEI that provides the complete finite element analysis and nozzle and pipe stress validation for engineers. With this integration, users can validate allowable local loads on cylinders and determine curve limits by using the built-in WRC 537 functionality in the software.

WRC 537 & Accurate Curve Calculations

In the WRC 537 bulletin, the document “Precision Equations and Enhanced Diagrams for Local Stresses in Spherical and Cylindrical Shells Due to External Loadings” outlines new figures and tables that have coefficients a-j for each curve printed.

These coefficients should be used in the formulas provided in the SR-1, SR-2, SR-3, SP-1 to SP-10 and SM-1 to SM-10 tables. These tables give guidance on allowable stresses for spherical shells, and Figures/Tables 1A to 4C are for stresses in cylindrical shells.

So, Why Use the WRC Method?

Simply, using the methods and tables provided in the WRC 537 bulletin aids in consistent accurate results. And since being just a pencil thickness off when reading the curves manually or with the human eye can create a big difference in the calculation, most engineers would be wise to not take the risk. Especially when time, money and safety are in the mix.

And time and again, using these formulas with the coefficients provided in the WRC 537 bulletin results in consistency and accuracy every time.

Using WRC 537 for Better Curve Results & Stress Analysis

In the latest releases of Finglow, determining local loads on cylinders and heads in accordance with ASME VIII Div, 1 and 2 are now streamlined with built-in WRC features.

Watch the Video to Learn More

For Local Loads on Cylinders

» The option to use WRC 537 curve fit data is now available in Finglow, which includes the selection of either the original or extrapolated curves.

» Finglow now has the capability to analyze a nozzle in a cylinder using the method provided in the WRC 107/537 bulletin.

» When performing a nozzle calculation to WRC 537 only, an option is now available to use data from the maximum stress curves Figure 1B-1 and 2B-1, which gives a conservative result.

For Local Loads on Heads

» The option to use WRC 537 curve fit data is now available in Finglow.

» As per the WRC 537 Section 3.5.2 guidelines, the use of the maximum values is permitted, which is the dashed line for the stress component in question in Figures SR-2 to SM-10 and has the designation Nx(MAX) for example.

Why Pressure Equipment Design Software Produces Safer Compliance

So while you're validating your pressure equipment against global codes like PD5500, EN13445 and ASME Section VIII, Div 1 and 2, allowable nozzle loads, curve fit data and overall stress calculations are more consistent when you use WRC features that are built into smart design software.

If you're interested in learning more about Finglow and it's latest features for better compliance design, Schedule a Discovery Call Today!

Leave a Comment