In 2019, Code Case 2901 (CC 2901) was incorporated to both ASME Section VIII, Division 1 (as UG-44(b)) and VIII, Division 2 (as 4.16.12) as an optional method for evaluating weld neck flanges for external loads. While external load consideration was always required under UG-22 in Division 1, now, an explicit method was given in the code as an option for the evaluation.

This inclusion of CC 2901 also marks the first times that the Division 1 and Division 2 have explicitly included a leakage-based methodology. Division 2, since its rewrite in 2007, has included explicit consideration for external loads in the custom flange methodology but for stress-based evaluations not leakage-based. The industry has long considered leakage-based assessments with the Kellogg method being the most well-known; it was only until 2019 that it was finally incorporated into pressure vessel code.

.jpg?width=3486&height=2324&name=kyle-levesque-TB-GyBM8Kpc-unsplash%20(1).jpg)

The inclusion of CC 2901 in the code has had some significant impact on the industry. Even though the code language in UG-44(b) and 4.16.12 says the method “may” be used, it has often been enforced as a mandatory requirement as these sections of the code are mandatory sections and alternatives are not explicitly provided or endorsed by the code. Many have considered the requirement too onerous as flange classes that have worked previously do not meet the method’s requirements now.

Additionally, recent shifts in ASME B31.3 piping code also includes references to CC 2901. The use of this method is becoming more standard in both pressure vessels and piping and yet is considered too conservative in many cases.

It is important to be familiar with the history and future of the method, as well as alternatives to the method. To help navigate through these options, our code experts offer some guidance for evaluating loads on flanged connections. Let’s dive in.

Methods for Standard ASME B16.5 and B15.47 Weld Neck Flanges

In July of 2013, Dr. Warren Brown’s PVPV2013-97814 paper1 was presented at the PVP Conference in Paris, France. This paper outlined a new method for evaluating standard ASME B16.5 and B15.47 weld neck flanges for pressure and external loads, using the pressure temperature ratings published in B16.5 and B16.47. The method is straight forward to apply:

- Using the flange type (weld neck, weld neck series A, or weld neck series B), the flange size (12”, 24”, etc.) and the flange class (150, 300, etc.), determine the moment factor, FM.

- Using the temperature under consideration, the flange material group and the flange class determine the pressure temperature rating, PR, from B16.5 or B16.47.

- Using the flange geometry and the gasket selection, the designer should determine the gasket reaction diameter, G.

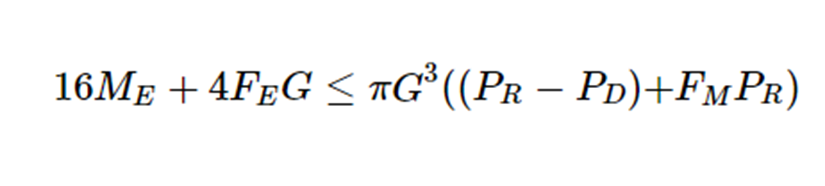

- Using the axial load, FE, external moment, ME, and the internal pressure, PD, the designer should then verify that the following expression is satisfied:

Comparison to Kellogg’s Equivalent Pressure Method

The Kellogg Equivalent Pressure method has long been used for the evaluation of flanged connections with external loads for leakage assessment. Using the same expression above, we get back to the Kellogg method simply by zeroing out the FM value. This means that the method introduced by Dr. Warren Brown ALWAYS gives a higher load capacity to weld neck flanges than the Kellogg method.

Code Case 2901 and UG-44(b)

Code Case 2901 adopted the methodology from the PVP2013-97814 paper and was approved for use in December of 2017. This was then incorporated into the code in the July 2019 publications of ASME Section VIII, Division 1 as UG-44(b) and ASME Section VIII, Division 2 as 4.16.12.

Since then, several code users feel the requirement was too arduous. This clearly raises the question that if Kellogg was the typical method for evaluating flanges, and if the UG-44(b) method is always more favorable to the designer, why is everyone complaining? Several complaints were based on switching methods for load evaluation, but a portion of the complaints came from the simple lack of consideration for external loads on a flange.

After a couple years of Code Committee debate and multiple iterations of proposals, a new version of Code Case 2901 was approved for public use in November 2023. This new version provides quite a bit of relief to the flange designer:

- The original FM values are limited to the weakest flange in the group. For example, all class 150 weld neck flanges that are NPS 12 or smaller, were given a FM value of 1.2.

- The expanded data shows that only NPS 8 and NPS 12 need to use 1.2, the other sizes have larger values. Some are several times larger.

It is still critical to understand how to read the code, even though these guides are provided. The consideration of the loads has long been required with the word “shall,” but the use of the UG-44(b) method was always optional with the word “may.” This distinction is important for code users in jurisdictions that may not allow code cases, given the code has NEVER required the application of UG-44(b). This still does not mean third party specifications or reviewers are not treating it as though it is required. For this reason, we may see UG-44(b) and 4.16.12 updated to reflect the latest release of CC 2901.

Alternatives and Supplements to UG-44(b)

There are lots of papers and methods available for evaluating external loads on flanges. When considering what method to use, the designer should consider the scope of the method and the basis for the method. For example, a stress-based method may not provide much insight as to whether leakage will occur. Below are a handful of methods with a brief description of scope and basis.

- Koves: The William Koves method described in the 2005 PVP paper “Design for Leaking in Flange Joints Under External Loads."2 This method applies only for B16.5 flanges (Size <= 24”) and can consider pressure and moment. This method does not reduce the pressure rating of the flange, but instead, determines an allowable moment for the flange in addition to the pressure. The method cannot be used for the B16.47 flanges, but it can be used for more than weld-neck flanges. The method does not have consideration for axial load and is a leakage-based assessment.

- Code Case 2901: As mentioned previously, CC 2901 was updated in November of 2023 with more favorable FM values. While it is at least as favorable to the designer as UG-44(b) is, the method allows for the consideration of weld-neck flanges, including series A and B, for all the sizes in B16.5 and B16.47. It can be used for axial load and moment consideration.

- Kellogg Equivalent Pressure: This is the most versatile but the most conservative of all the leakage-based methods listed. If the flange under consideration is a weld neck, there is no reason to use this over UG-44(b). The strength of this method is that it fills in some scope gaps for things like slip on flanges that are not covered already.

- 4.16: This is the D2 custom flange method. This is a stress-based method and is not based on the pressure ratings from B16.5 or B16.47. The real strength of employing this method is that it is not a code case or “industry practice” as it is already placed in the code book itself. It is easy to get to this method following U-2(g) for Division 1 vessels.

- EN-1591: This method is leakage-based and comes from the EN code. Specifically, EN13445-3 Annex G, which uses the Alternative (Wölfel) method. While this method only covers narrow faced joints, the most notable features must be the use of limit analysis, the recognition that the bolt load has its own tolerance, the calculation of the way the bolt load changes as pressure (or other loads) are applied and the detailed analysis of gasket behavior.

Navigating the Future: Embracing Innovation in Load Evaluation

The incorporation of Code Case 2901 (CC 2901) into ASME Section VIII, Division 1 and Division 2 introduced leakage-based assessment into the code while providing an explicit option for external load evaluation on flanges. This marked a departure from traditional stress-based evaluations, like 4.16. However, the initial misapplication of UG-44(b) as a mandatory requirement faced criticism for its perceived burden on designers, prompting revisions and updates to CC 2901 to provide more favorable conditions.

The evolution of Code Case 2901 reflects a broader trend in the industry towards standardized methodologies for load evaluation, with references to CC 2901 now appearing in ASME B31.3 piping code. Despite initial resistance and concerns over conservatism, the revised version of CC 2901 offers relief to designers while maintaining the importance of understanding and navigating through various evaluation methods.

Furthermore, alternatives and supplements to CC 2901 provide additional avenues for evaluating external loads on flanges, each with its own scope and basis.

As the industry continues to evolve and standards adapt to new challenges, staying informed about the available evaluation methods and advancements in technology remains crucial for ensuring the safety and reliability of pressure vessels and piping systems. By embracing innovative methodologies and leveraging technological solutions, engineers can navigate through complex, yet common, load evaluation scenarios with confidence and precision, ultimately contributing to the advancement of engineering practices and safety standards in the field.

Code-Assistance Software and the Reliability of Automated FEA

Code-assistance software and automated finite element analysis tools further enhance the reliability and efficiency of load evaluation processes, empowering designers to validate their designs against multiple methods and updated code requirements.

Between our suite of design solutions for pressure vessels, heat exchangers, and their related components, our code-assistance software like DesignCalcs and Finglow incorporates several methods for evaluating external loads. From Appendix 2, 4.16, Taylor Forge Bulletin 502, EN-1591, B16.5 and B16.47 Pressure Temperature Ratings, Koves, UG-44(b) and Kellogg, users can easily validate their flange designs against these methods and against the most updated requirements of ASME Section VIII, Div 1, Div 2, and EN 13445 as well as PD 5500.

Additionally, our colleagues at Paulin Research Group provide automated finite element analysis (FEA) for flanged joints and other axisymmetric geometries, 3D models, and non-linear finite element models of gaskets, bolts, and flanges. The software automatically identifies the stresses, displacements, and leakages in and around each flange joint in a design. The model is then automatically validated against ASME Section VIII, Div 1 Appendix 2, ASME BFJ, and EN 13445 Annex G. Code reports are displayed as PDFs that can be downloaded, emailed, or printed with additional review parties.

References

1 Brown, Warren. "Improved Analysis of External Loads on Flanged Joints." ASME Digital Collection, American Society of Mechanical Engineers Digital Collection, 17 January 2014, asmedigitalcollection.asme.org/PVP/proceedings-abstract/PVP2013/55676/V003T03A026/284093.

2 Koves, William J. “Design for Leakage in Flange Joints under External Loads.” ASME Digital Collection, American Society of Mechanical Engineers Digital Collection, 1 May 2006, asmedigitalcollection.asme.org/pressurevesseltech/article-abstract/129/2/334/471674/Design-for-Leakage-in-Flange-Joints-Under-External?redirectedFrom=fulltext.

Leave a Comment