Contact

|

About

|

Support

|

816-228-2976

Blog

Code Updates

Insight on Q3 2025 ASME Boiler and Pressure Vessel Code Meetings

By CEI

| 25, August 2025

READ NOW

SUBSCRIBE TO THE THINK TANK

Thanks for submission!!

Insight on Q3 2025 ASME Boiler and Pressure Vessel Code Meetings

posted at Aug 25, 2025

Webinar Recap: 2025 Code Changes | ASME, AWS & More

posted at Aug 19, 2025

Top Engineering Flange Design Workarounds

posted at Aug 8, 2025

ASME Section VIII Reshape Initiative: Engineering Insights on Code Shifts

posted at Jul 16, 2025

Case Study: How ProWrite Helped Helfrich Brothers Regain Control of Welding Records

posted at Jun 3, 2025

Posts by Topic

- Blog (56)

- Code Updates (24)

- Weld Procedure (20)

- Pressure Vessel Design (16)

- Webinars (13)

- Code Compliance (4)

- Flange Design (3)

- Piping (2)

- Piping Software (2)

- Case Study (1)

- Code Software (1)

- Conference (1)

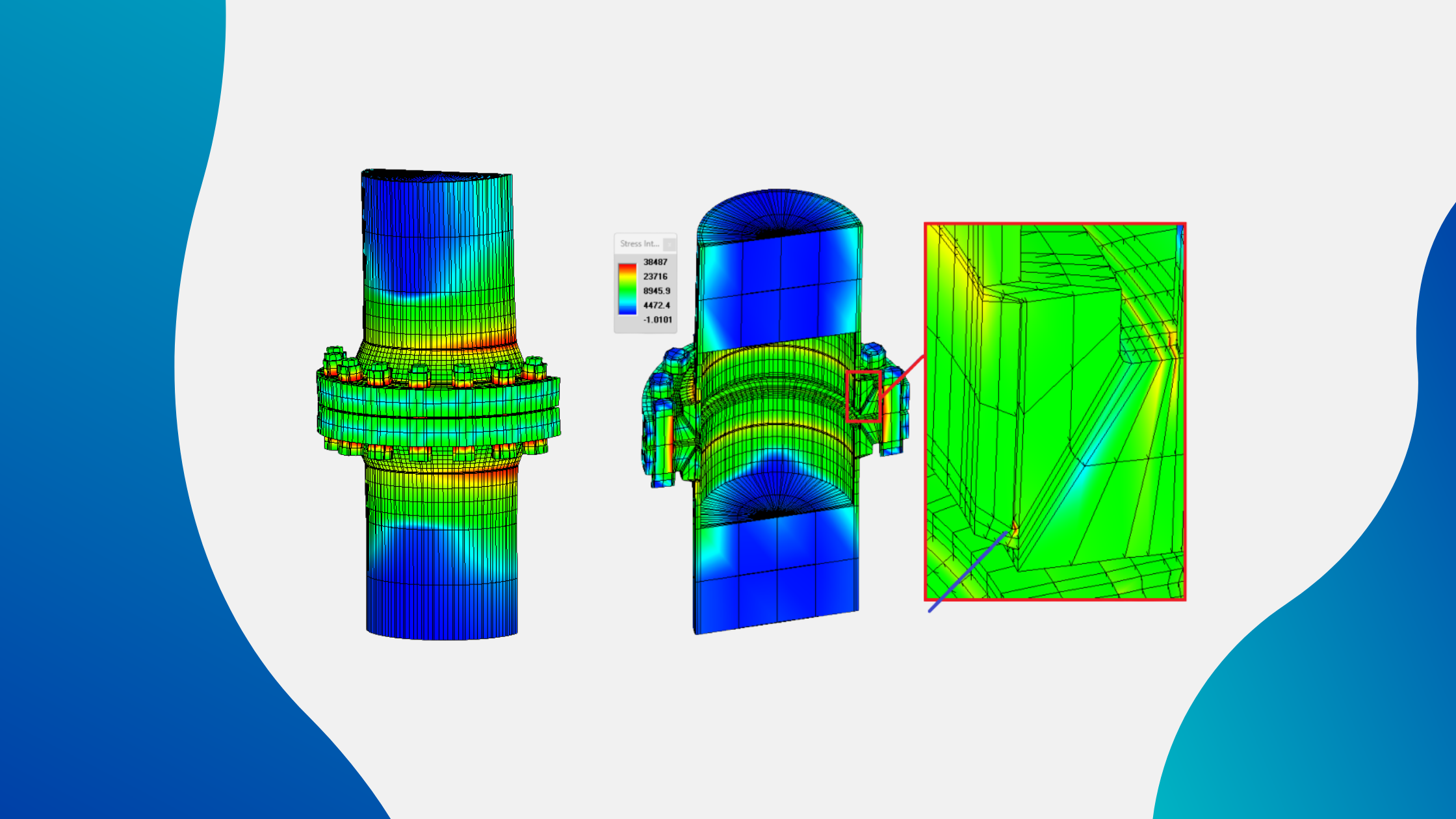

- FEA (1)

- Linear Analysis (1)

- Non Linear Analysis (1)

- Nozzle Loadings (1)

- Paulin Research Group (1)

- Pressure Vessel Design Software (1)

- Stress Analysis (1)

- WRC (1)

- WRC 537 (1)

Leave a Comment